Save costs. Why not save on pollution?

Companies always want to cut costs in order to remain competitive. We reduce costs through a procurement market that still receives too little attention.

Where do our raw materials come from?

Many manufacturing companies are constantly on the lookout for the cheapest Asian supplier for their raw material requirements. Morphosa Berlin has already made a find in this area. We access Germany's inconspicuous treasures: plastic waste from commercial and private use.

More than half of the world's plastic is produced in Asia. Around a third of the world's plastic volume is produced in China alone. In 2020, the global production volume of plastic amounted to around 367 million tons. The transit route from China to Germany is usually around 8000 km. This transport route is accepted cheaply along the entire western economic structure in order to benefit from the low wage situation there.

Source: Statista

According to the BKV's material flow diagram study, plastics consumption in Germany amounted to 12.1 million tons in 2019 after adjustment for imports and exports. This compares to a volume of 6.28 million tons of plastic waste. In relation to 6.02 million tons in 2017, the amount of plastic waste increased by 2.0 %. Of this waste, 85.2% is generated by end consumers. The remaining 14.8% was generated during the production and, above all, processing of plastics.

In addition, just over 1.9 million tons of recyclates were processed in 2019. The proportion of recycled plastic in the total amount of plastic processed was therefore 13.7%. Even though the proportion of recycled plastic in the plastics industry has fortunately increased, the value is far too low for society to live in harmony with nature in the long term.

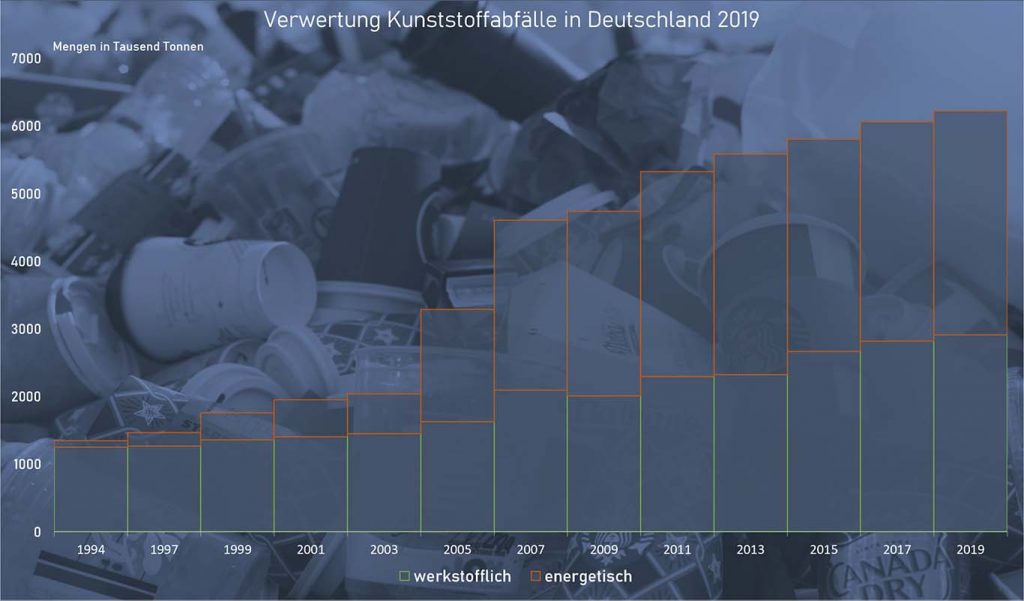

Although it may seem positive that over 99% of all collected plastic waste was recycled in 2019, the high proportion of energy recovery unfortunately clouds the result. The data published by the Federal Environment Agency on the development of plastic waste recycling provides an indication of two things: firstly, plastic waste in Germany has risen steadily by around 5% annually. Secondly, the percentage of material reuse averages around 2%. At the same time, over 50% of plastic waste is used to generate energy, i.e. incinerated.

SOURCE: Umweltbundesamt 2020, Plastics in Germany 2019 (as of 08/2020)

The differences in the recycling of plastic waste have a significant influence on this result. This is because the recycling rate from plastic production (industry) reached 84% in 2019, while only 33% of plastic waste from private households was recycled that year. The reason for these different rates is that plastics in industry are usually very clean and sorted, but in households and many commercial enterprises they are contaminated and mixed.

It is still unclear how the pandemic has affected plastic consumption and the Federal Environment Agency is working on determining the figures for 2020 to date.

75 kg of plastic waste per capita in Germany

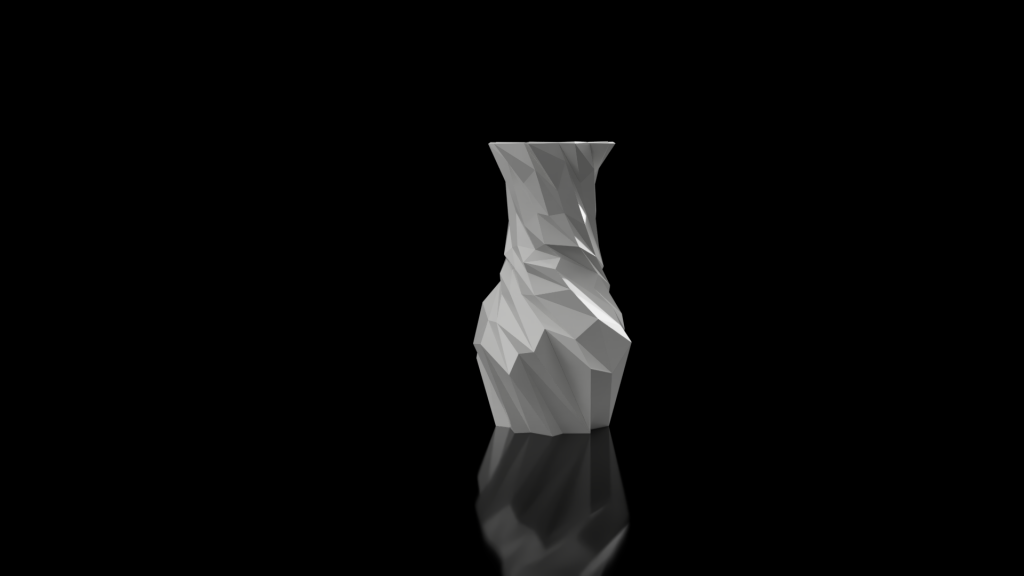

Vase Monolith

Rechnerisch fallen somit pro Kopf 75,4 Kg Kunststoffabfälle jährlich in Deutschland an. Für die Produktion unserer Vase „Da Vinchy“, der Monolith Serie entspräche diese jährliche Menge ungefähr 785 Vasen. Aus diesem Grund ist die Produktion dieser Vase auf 785 Stück limitiert.

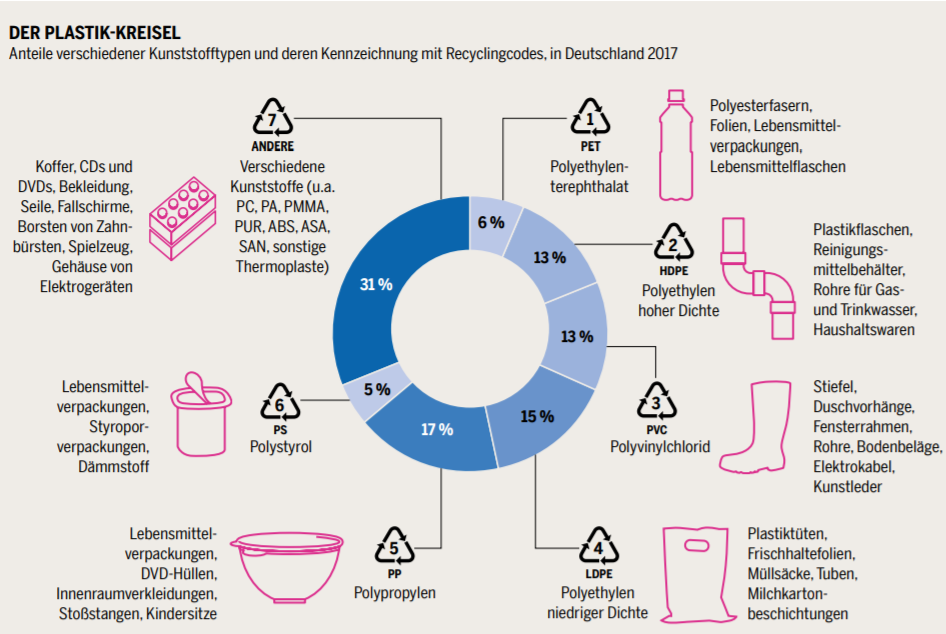

Types of plastic in the German recycling system

69.2 % of the plastics processed were made of the following five thermoplastics (includingRezyklate):

- Polyethylene (PE) with 3.94 million tons (mt),

- olypropylene (PP) with just under 2.41 million tons,

- Polyvinyl chloride (PVC) with 1.82 million tons,

- Polyethylene terephthalate (PET) with 957,000 tons and

- Polystyrene and expanded polystyrene (PS/PS-E) with 727,000 tons.

Around 14% of the total volume produced were other thermoplastics such as polycarbonate (PC), polyamide (PA) or styrene copolymers such as acrylonitrile-butadiene-styrene (ABS) and styrene-acrylonitrile (SAN). The remaining 17% were other plastics, including thermosets such as epoxy, phenolic and polyester resins as well as polyurethanes and mixed plastic recyclates.

Packaging remains the largest area of application for plastics. 30.7% of the plastics processed in Germany were used here in 2019. The construction sector took second place with 25.2%. This was followed by the automotive industry with 10.6% and electrical and electronic equipment with 6.2%.

SOURCE: Umweltbundesamt 2020

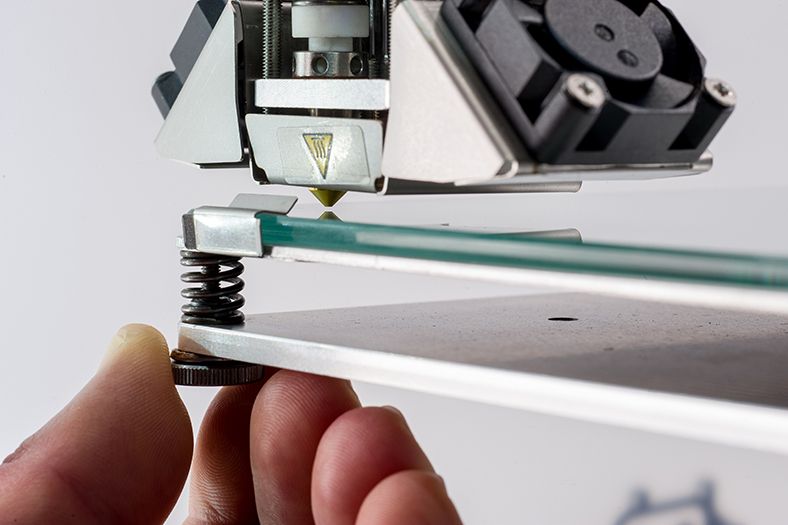

Wide range of applications for the FDM 3D printing process

Thanks to Fused Deposition Modelings, we are able to utilize the different properties of various polymers (plastics) using specially equipped 3D printers to create designs with unique shapes and durability.

We are currently able to reuse the following materials:

- PLA

- ABS

- PET

- PE

- PP

- PVC

Creating new awareness - for industry and society

Morphosa Berlin exists because not enough has been achieved in our thinking and in the recycling industry. As the Federal Environment Agency suggests, an increase in plastics recycling can be achieved if a more differentiated separation of used plastics can be achieved, particularly in the area of commercial and private waste.

Even though the importance of protecting our environment has largely been recognized, we are convinced that the demand for recycled products from end consumers should increase in order to steer the global industry in the right direction.

With the aim of changing the perception of consumers and manufacturers, we are dedicated to unique designs made from recycled materials.

Join the journey together and follow us on the way via our blog, newsletter, Instagram and Pinterest!